Overview

TASK-LINE® Design

Through a proprietary process, FDA approved, pure virgin PTFE resin is compression molded around and through a 304 stainless steel, perforated metal insert. After oven sintering, every gasket undergoes a 15,000-volt spark test to check for pinholes. The porous-free PTFE resin 100% encapsulates the stainless insert, isolating it from any fluid contact while in service.

No More Fabrication; Easy Installation

TASK-LINE gaskets are molded to size, 1/2" through 24" in class 150# and 300# ANSI ratings with a thickness of 1/8 " or 3/32 " (other thicknesses available upon request). Installation is quick and simple. TASK-LINE gaskets are self-aligning and seat easily to any flange in almost any condition.

TASK-LINE® Benefits

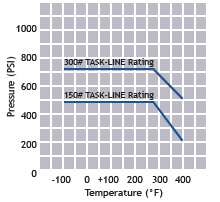

TASK-LINE gaskets have a temperature range of cryogenic to 400°F (consult factory for higher temperatures) and are chemically resistant to: all acids, all chlorides, all sulfates, all bleach solutions, all solvents, all phenols, all caustics, and all peroxides. TASK-LINE gaskets are leak-free and bubble-tight and can be used over and over without sacrificing sealing ability. TASK-LINE gaskets have zero corrosion rates which contribute to lower life-cycle costs when compared to envelope or solid gasket types.

TASK-LINE® Advantages

- Maximum protection

- Zero corrosion rate

- No retorquing after installation

- Blowout protection

- No fabrication or waste

- Reusable

- Non-porous

- Seats easily / releases easily

- Cryogenic to +400°F (204°C)

Performance

Pressure-Temperature

Limits

In terms of performance and longevity, nothing comes close. When installed between two flanges, the PTFE encapsulated metal insert restricts the PTFE from cold flow/creep while under load. The metal insert prevents radial flow of the gasket which eliminates bolt retorquing after installation, maintaining a tight seal even through repeated temperature cycles. The strength of the metal insert also provides critical, blowout-proof protection. Another benefit of TASK-LINE gaskets is the PTFE's non-stick property which allows it to easily release from flanges during disassembly without any scraping.

| TASK-LINE Gaskets Sizing Table and Part Numbers | ||||

|---|---|---|---|---|

| Other sizes available upon request. | ||||

| Size (in) |

Part Number (150# Flange) |

ID × OD | Part Number (300# Flange) |

ID × OD |

| 1/2 | TLG0050 | .590 × 1.875 | 3TLG0050 | .590 × 2.125 |

| 1/2 ANSI | ATLG0050 | .840 × 1.875 | A3TLG0050 | .840 × 2.125 |

| 3/4 | TLG0075 | .750 × 2.250 | 3TLG0075 | .750 × 2.625 |

| 3/4 ANSI | ATLG0075 | 1.080 × 2.250 | A3TLG0075 | 1.060 × 2.625 |

| 1 | TLG0100 | 1.030 × 2.625 | 3TLG0100 | 1.030 × 2.875 |

| 1 ANSI | ATLG0100 | 1.310 × 2.625 | A3TLG0100 | 1.310 × 2.875 |

| 1-1/4 | TLG0125 | 1.375 × 3.000 | 3TLG0125 | 1.375 × 3.250 |

| 1-1/4 ANSI | ATLG0125 | 1.660 × 3.000 | A3TLG0125 | 1.660 × 3.250 |

| 1-1/2 | TLG0150 | 1.590 × 3.375 | 3TLG0150 | 1.500 × 3.750 |

| 1-1/2 ANSI | ATLG0150 | 1.910 × 3.375 | A3TLG0150 | 1.900 × 3.750 |

| 2 | TLG0200 | 2.060 × 4.125 | 3TLG0200 | 2.060 × 4.375 |

| 2 ANSI | ATLG0200 | 2.375 × 4.125 | A3TLG0200 | 2.375 × 4.375 |

| 2-1/2 | TLG0250 | 2.470 × 4.875 | 3TLG0250 | 2.470 × 5.125 |

| 2-1/2 ANSI | ATLG0250 | 2.875 × 4.875 | A3TLG0250 | 2.875 × 5.125 |

| 3 | TLG0300 | 3.060 × 5.375 | 3TLG0300 | 3.060 × 5.875 |

| 3 ANSI | ATLG0300 | 3.500 × 5.375 | A3TLG0300 | 3.500 × 5.875 |

| 4 | TLG0400 | 4.000 × 6.875 | 3TLG0400 | 4.000 × 7.125 |

| 4 ANSI | ATLG0400 | 4.500 × 6.875 | A3TLG0400 | 4.500 × 7.125 |

| 5 | TLG0500 | 5.030 × 7.750 | 3TLG0500 | 5.030 × 8.500 |

| 5 ANSI | ATLG0500 | 5.560 × 7.750 | A3TLG0500 | 5.560 × 8.500 |

| 6 | TLG0600 | 6.000 × 8.750 | 3TLG0600 | 6.000 × 9.875 |

| 6 ANSI | ATLG0600 | 6.625 × 8.750 | A3TLG0600 | 6.625 × 9.875 |

| 8 | TLG0800 | 8.000 × 11.000 | 3TLG0800 | 8.000 × 12.125 |

| 8 ANSI | ATLG0800 | 8.625 × 11.000 | A3TLG0800 | 8.625 × 12.125 |

| 10 | TLG1000 | 10.000 × 13.375 | 3TLG1000 | 10.000 × 14.250 |

| 10 ANSI | ATLG1000 | 10.750 × 13.375 | A3TLG1000 | 10.750 × 14.250 |

| 12 | TLG1200 | 12.000 × 16.125 | 3TLG1200 | 12.000 × 16.625 |

| 12 ANSI | TLG1200 | 12.750 × 16.125 | ATLG1200 | 12.750 × 16.625 |

| 14 | TLG1400 | 13.250 × 17.750 | 3TLG1400 | 13.250 × 19.125 |

| 14 ANSI | ATLG1400 | 14.000 × 17.750 | A3TLG1400 | 14.000 × 19.125 |

| 16 | TLG1600 | 15.500 × 20.250 | 3TLG1600 | 15.500 × 21.25 |

| 18 | TLG1800 | 17.500 × 21.625 | 3TLG1800 | 17.500 × 23.500 |

| 20 | TLG2000 | 19.250 × 23.875 | 3TLG2000 | 19.250 × 25.750 |

| 24 | TLG2400 | 23.250 × 28.250 | 3TLG2400 | 23.250 × 30.500 |

ASTM A193 Gr. B7 Lubricated Bolt

ASTM A194 Gr. 2H Nut

Friction factor = 0.13

| TASK-LINE Torque Guidelines - Class 150 | |||||

|---|---|---|---|---|---|

| Other sizes available upon request. | |||||

| Size | Bolting Required | Min. Torque (Ft-Lb) | Nominal Torque (Ft-Lb) | Max Torque (Ft-Lb) | Bolt Yield Torque (Ft-Lb)* |

| 1/2" | (4X) 1/2"-13 | 25 | 40 | 60 | 112 |

| 3/4" | (4X) 1/2"-13 | 25 | 40 | 60 | 112 |

| 1" | (4X) 1/2"-13 | 30 | 45 | 60 | 112 |

| 1-1/4" | (4X) 1/2"-13 | 30 | 45 | 60 | 112 |

| 1-1/2" | (4X) 1/2"-13 | 30 | 45 | 60 | 112 |

| 2" | (4X) 5/8"-11 | 40 | 60 | 90 | 218 |

| 2-1/2" | (4X) 5/8"-11 | 40 | 60 | 90 | 218 |

| 3" | (4X) 5/8"-11 | 60 | 80 | 90 | 218 |

| 4" | (4X) 5/8"-11 | 45 | 60 | 90 | 218 |

| 6" | (8X) 3/4"-10 | 90 | 140 | 150 | 384 |

| 8" | (8X) 3/4"-10 | 160 | 180 | 190 | 384 |

| 10" | (12X) 7/8"-9 | 220 | 240 | 270 | 614 |

| 12" | (12X) 7/8"-9 | 220 | 240 | 270 | 614 |

| 14" | (12X) 1"-8 | 365 | 380 | 450 | 914 |

| 16" | (12X) 1"-8 | 365 | 400 | 450 | 914 |

| 18 | (16X) 1-1/8"-7 | 530 | 560 | 640 | 1272 |

| 20 | (16X) 1-1/8"-7 | 480 | 530 | 640 | 1272 |

| 24 | (20X) 1-1/4"-7 | 670 | 700 | 800 | 1900 |

| TASK-LINE Torque Guidelines - Class 300 | |||||

|---|---|---|---|---|---|

| Other sizes available upon request. | |||||

| Size | Bolting Required | Minimum Torque (Ft-Lb) | Nominal Torque (Ft-Lb) | Maximum Torque (Ft-Lb) | Bolt Yield Torque (Ft-Lb)* |

| 1/2" | (4X) 1/2"-13 | 35 | 50 | 60 | 112 |

| 3/4" | (4X) 5/8"-11 | 35 | 50 | 60 | 218 |

| 1" | (4X) 5/8"-11 | 40 | 50 | 60 | 218 |

| 1-1/4" | (4X) 5/8"-11 | 60 | 80 | 120 | 218 |

| 1-1/2" | (4X) 3/4"-10 | 60 | 80 | 120 | 384 |

| 2" | (8X) 5/8"-11 | 45 | 70 | 90 | 218 |

| 2-1/2" | (8X) 3/4"10 | 50 | 80 | 120 | 384 |

| 3" | (8X) 3/4"10 | 65 | 90 | 120 | 384 |

| 4" | (8X) 3/4"10 | 80 | 115 | 150 | 384 |

| 6" | (12X) 3/4"-10 | 60 | 80 | 120 | 384 |

| 8" | (12X) 7/8"-9 | 140 | 155 | 180 | 614 |

| 10" | (16X) 1"-8 | 165 | 210 | 350 | 914 |

| 12" | (16X) 1-1/8"-7 | 250 | 275 | 400 | 1272 |

| 14" | (20X) 1-1/8"-7 | 280 | 330 | 580 | 1272 |

| 16" | (20X) 1-1/4"-7 | 420 | 480 | 800 | 1900 |

| 18 | (24X) 1-1/4"-7 | 505 | 540 | 850 | 1900 |

| 20 | (24X) 1-1/4"-7 | 530 | 565 | 1000 | 1900 |

| 24 | (24X) 1-1/2"-6 | 720 | 755 | 1300 | 3416 |

* : Yield taken from root area of bolt

All torque values are based on the MAWP of 500 psig internal fluid pressure. If lower pressures are to be sealed, lower torque values are applicable.