400 Series Overview400 Series, 405 Series, 450 Series, 455 Series, 459 Series

The Strongest, Lightest, most Chemically Resistant Valve in the World

- Corrosion Resistant

- Strong as Steel

- 1/2 the weight of Steel

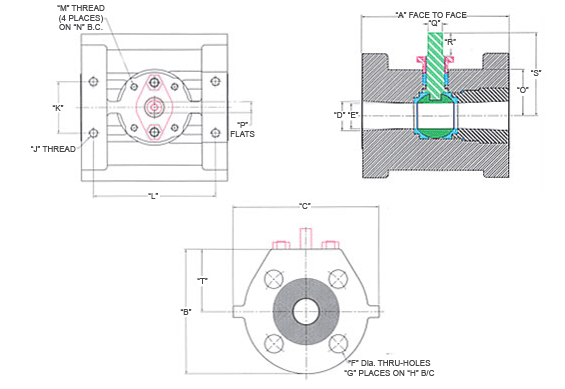

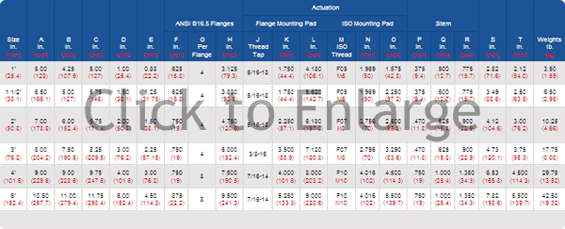

The PureFlex 400 Series composite ball valve is a superior quality, ANSI Class 150 valve engineered with features not yet available in any other composite ball valve. Manufactured from advanced premium Derakane® 470 grade vinyl ester or E-Plus™ epoxy resin reinforced with fiberglass or carbon graphite, the valve is able to withstand severe corrosive media as well as hostile environments up to 275°F. The 400 series ball valve exceeds Class VI shut-off and its stem seal will meet your routine or most demanding service requirements. The massive one piece body meets ANSI B16.10 dimensions and its ISO 5211 universal mounting pad and flange mounting makes automation simple even with the valve in service. The 400 series valves are ½ the weight of alloy valves and offer maximum corrosion resistance, the elimination of product contamination, and provide the ultimate in flexibility and value.

400 Series

The 400 series valve is manufactured from advanced premium Derakane® 470 vinyl ester resin reinforced with glass fibers. It is highly corrosion resistant and is suitable for many chemicals from -50ºF to +215ºF up to 275 psi. Size range 1" - 10".

405 Series

The 405 series valve is manufactured from advanced premium Derakane® 470 vinyl ester resin reinforced with carbon graphite fibers. It is highly corrosion resistant and is suitable for many chemicals from -50ºF to +250ºF up to 275 psi. Valve is static dissipative, having less than 10³ ohms cm sustain resistivity.

450 Series

The 450 series valve is manufactured from advanced E-Plus™ epoxy resin reinforced with glass fibers. It has outstanding corrosion resistance to solvents and is suitable for many chemicals from -50ºF to +225ºF up to 275 psi. Size range 1" - 10".

455 Series

The 455 series valve is manufactured from advanced E-Plus™ epoxy resin reinforced with carbon graphite fibers. It has outstanding corrosion resistance to solvents and is suitable for many chemicals from -50°F to +275°F up to 275 psi. Size range 1" - 10". Valve is static dissipative, having less than 10³ ohms cm sustain resistivity.

459 Series Ceramic Lined

The PureFlex 459 Series ceramic-lined composite ball valve is a superior quality, ANSI Class 150 valve engineered with features not yet available in any other ceramic valve. The valve body is manufactured from strong, light weight advanced premium E-Plus™ epoxy resin reinforced with carbon graphite. The ceramic liner / seats and ball are partially stabilized zirconia (PSZ) which provides unmatched impact resistance. The valve is able to withstand abrasion, cavitation, wear, thermal cycling, and severe corrosive media and environments up to 275°F. The 459 Series ball valve exceeds Class IV shut-off and its stem seal will meet your routine or most rigid service requirements. The massive one piece body meets ANSI B16.10 dimensions and its ISO 5211 universal mounting pad and flange mounting makes automation simple even with the in service. The 459 Series valves are 1/2 the weight of competitors' ceramic valves, offer maximum corrosion resistance and the elimination of product entrapment, and provide the ultimate in flexibility and value.

Learn MoreFeatures

-

Wrench

Locking wrench manufactured from

Durcor-62™ vinyl ester is virtually unbreak-

able. Lifetime warranty against failure of any

kind. -

Wrench Stop

Independent locking wrench stop is bolted to valve body and not connected to packing gland in any way. Prevents unnecessary gland movement and stem side loading.

-

Valve Body

One piece massive valve body is light weight, rugged and is as corrosion resistant on the outside as it is on the inside to resist environmental attack. Valve body end cap is sealed with PTFE diametrical seal locked in compression to eliminate cold flow. The valve body meets ANSI B16.10 and flange connections are compliant to ASME B16.5 Class 150. ISO 5211 and flange actuator mounting pads are standard.

-

Packing Gland adjustment

Stud and nut design, standard material is Hastelloy® C276. Designed to minimize valve body stress when adjustment is required.

-

Live loaded

Packing gland is live loaded with Belleville washers, eliminating unnecessary adjustment and aids in reducing stem emissions.

-

Packing Gland

Packing gland standard materials is Hastelloy® C276 and is guaranteed not to corrode in hostile enviroments.

-

Valve Stem - Blow-Out Proof

Stem insert is Hastelloy® C276 encapsulated with either carbon graphite reinforced vinyl ester or E-Plus™ epoxy resin.

-

Stem Bearing

Graphite / PTFE Radial bearing prevents stem side loading aiding in eliminating emissions and extending packing life.

-

Stem Sealing

Chevron PTFE packing provides positive stem sealing while mainaining low turning torque.

-

Thrust Bearing

Graphite / PTFE stem thrust bearing maintains low turning torque.

-

Valve Ball

Ball material is carbon graphite reinforced vinyl ester or E-Plus™ epoxy. Ball O.D. is micro polished to provide longer seat life.

-

Seat Energizer

FEP encapsulated Viton® O-rings energize seats to ball and aid in bubble tight shut-off at low pressures.

-

Seat

PTFE cavity filled seats minimize cavity around ball which could retain process media. Other seat materials available.

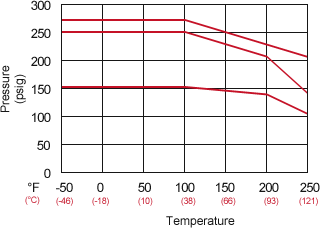

Technical Data

Pressure/Temperature Curve

| Cv DATA | |

|---|---|

| *Consult Factory | |

| Valve Size | Full Open Cv |

| 1" | 45 |

| 1 1/2" | 120 |

| 2" | 165 |

| 2 1/2" | *CF |

| 3" | 350 |

| 4" | 550 |

| 5" | *CF |

| 6" | 1245 |

| 8" | *CF |

| 10" | *CF |

| Actuator Sizing | |

|---|---|

| *Consult Factory | |

| Valve Size | Torque @ Max. Diff. PSI |

| 1" | 140 in.-lbs |

| 1 1/2" | 195 in.-lbs |

| 2" | 230 in.-lbs |

| 2 1/2" | *CF |

| 3" | 615 in.-lbs |

| 4" | 1155 in.-lbs |

| 5" | *CF |

| 6" | 2150 in.-lbs |

| 8" | *CF |

| 10" | *CF |

Parts List & Materials

| Parts List & Materials | ||||

|---|---|---|---|---|

| Item | Description | Standard Material | QTY | |

| 1 | Body 400 | Derakane® 470 Vinyl Ester / Fiberglass | 1 | |

| 405 | Derakane® 470 Vinyl Ester / Carbon | |||

| 450 | Epoxy E-Plus™ / Fiberglass | |||

| 455 | Epoxy E-Plus™ / Carbon | |||

| 2 | Stem 400 & 405 | Derakane® 470 Vinyl Ester / Carbon / Hastelloy C276 Insert | 1 | |

| 450 & 455 | Epoxy E-Plus™ / Carbon / Hastelloy C276 insert | |||

| 3 | Ball 400 & 405 | Derakane® 470 Vinyl Ester / Carbon | 1 | |

| 450 & 455 | Epoxy E-Plus™ / Carbon | Optional Materials | ||

| 4 | Seat - Cavity Filled | PTFE | 2 | Glass Filled PTFE/UHMWPE |

| 5 | Seat Energizer Ring | FEP Encapsulated Viton® | 2 | Hastelloy® C-276 |

| 6 | End Cap Diametrical seal | PTFE | 1 | |

| 7 | End Cap 400 | Derakane® 470 Vinyl Ester / Fiberglass | 1 | |

| 405 | Derakane® 470 Vinyl Ester / Carbon | |||

| 450 | Epoxy E-Plus™ / Fiberglass | |||

| 455 | Epoxy E-Plus™ / Carbon | |||

| 8 | Thrust Bearing | PTFE / Graphite | 1 | |

| 9 | Chevron Packing | PTFE | 1 | |

| 10 | Stud - Packing Gland | Hastelloy® C-276 (UNS N10276) | 2 | |

| 11 | Radial Bearing | PTFE / Graphite | 1 | |

| 12 | Packing Gland | Durcor 62™ | 1 | |

| 13 | Gland Nut | Hastelloy® C-276 (UNS N10276) | 2 | |

| 400 Series Ball Valve Handle Option | ||

|---|---|---|

| Item | Decription | Standard Material |

| 1 | Wrench - Locking | Durcor-62™ |

| 2 | Hex Head Cap Screw | 316 Stainless Steel |

| 3 | Washer | 17-7 ph Stainless Steel |

| 4 | Wrench Stop Plate - Locking | 304 Stainless Steel |